FBN custom manufactures a unique cap chuck design for any customer in need. Providing better speed and consistency to operations, our cap chucks are trusted throughout a variety of industries for their bottling operations. Through collaboration with our skilled team of engineers, custom cap chucks work to provide your workflow with a better solution to capping. From these custom adjustments to the standard features, our cap chucks are sure to improve your operations.

Cap Chuck Features

1

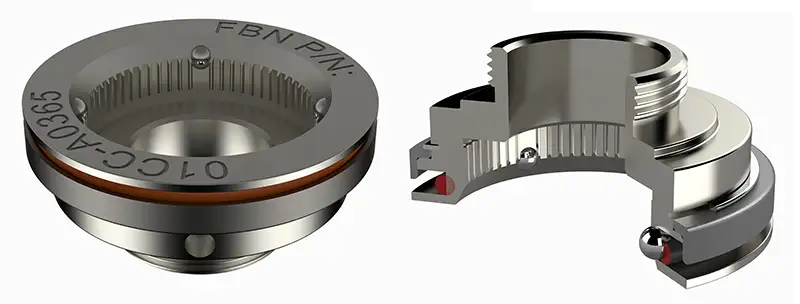

Custom Serrations

Our cap chucks feature custom serrations designed to precisely match the cap knurl design, ensuring a secure fit and efficient operation.

- Precise torque transmission: Serrations facilitate accurate transmission of torque from the spindle to the cap, enhancing performance.

- Cap Marking Prevention: By aligning perfectly with the cap knurl, serrations help prevent any damage or marking on the caps.

2

Laser-Etched

For easy identification and customization, our cap chucks come laser-etched.

- Easy identification: Each cap chuck is clearly marked for quick and easy identification.

- Custom marking: Available upon request to suit your specific needs.

3

Multiple Configurations Available

We offer a variety of configurations to match any Original Equipment Manufacturer (OEM) cap chuck. This ensures compatibility and ease of integration into your existing systems.

4

Quick-Change Option Available

Our cap chucks are designed with a quick-change option to streamline your operations. This helps to minimize downtime and maximize productivity.

5

O-Ring “Keeper”

The innovative O-Ring “Keeper” feature enhances the functionality and reliability of our cap chucks.

- Prevents loss: The unique design eliminates the potential of losing the o-ring.

- Protects ball environment: This feature maintains o-ring visibility while protecting the internal components.

6

Maximum Lead-In

Our cap chucks are engineered with maximum lead-in to minimize missed applications.

- Minimize errors: Our cap chuck design reduces the likelihood of missed cap applications.

- Ensure repeatability: Helps ensure repeatable and reliable cap pick-up, improving overall efficiency.

7

Offset Ball Position

The offset ball position in our cap chucks offers superior handling capabilities.

- Enhance handling: Through our design, you gain better control and handling of caps.

- Prevent binding: The offset ball position helps you operate a smoother system without binding on the cap. This improves both reliability and performance of the overall system.

8

Detail Focused

- Careful attention to even the very smallest detail.

- Helps prevent caps from being marked.

Why Choose Our Cap Chucks?

Our cap chucks are engineered for precision and reliability. Through a unique design, they ensure your capping process runs more smoothly and efficiently. With features tailored to meet the highest standards of performance, our cap chucks offer unmatched durability and ease of use. Whether you require custom serrations, laser-etched identification, or a quick-change option, our products are designed to meet your specific needs and exceed your expectations. Trust in our cap chucks to provide the powerful performance and longevity your operation demands.