In the bottling industry, slide rods play a critical role in the precise operation of filling machines. Understanding the differences and similarities between one-piece and two-piece slide rods is essential for choosing the right component. Depending on what your operation needs, each option provides a variety of benefits that are sure to improve your workflow.

FBN Sales manufactures slide rod assemblies for different industries and their bottling operations. Depending on what equipment you’re working with, our expert technicians can provide durable, dependable one-piece or two-piece slide rod replacements for your gear.

SIMILIARITIES

Material and Manufacturing

High-Quality Construction: Both one-piece and two-piece slide rods are CNC machined from solid bar stock. This provides maximum strength and durability. This precision manufacturing process also provides high tolerance and excellent performance in demanding environments.

Engineered Polymer Bushings: Both designs feature proprietary snap-in bushings made from engineered polymer materials. These bushings offer superior lubrication, preventing metal-to-metal contact. This enhances the stability and lifespan of the slide rods.

Design Features

Support Rod Precision: Both one-piece and two-piece slide rods have support rods that are ground and polished to +/- .0005 tolerance. This ensures a precise fit and smooth operation.

Cam Block Design: The cam blocks in both designs are 100% CNC machined from solid stock and are reversible for clockwise or counterclockwise rotation. This provides flexibility and reliability in various operational settings.

DIFFERENCES

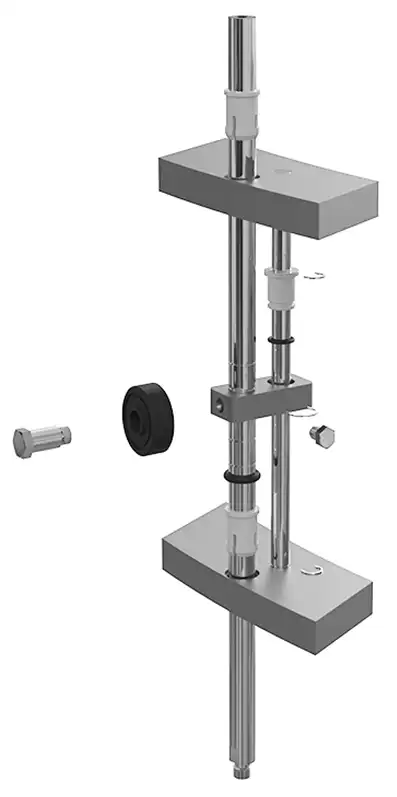

One-Piece Slide Rod

Single Unit Construction: The one-piece slide rod is a single, continuous component. This offers a straightforward design that simplifies the overall structure.

Height Adjustment: This design features multiple snap ring grooves for simple height adjustment. This allows for easy customization to fit different operational requirements.

Durability: With its single-unit construction, the one-piece slide rod is highly durable and offers long-lasting performance with minimal maintenance.

Simplified Design: The simplicity of the one-piece slide rod design can be advantageous in applications where frequent disassembly is not required. This provides a simple, but reliable solution.

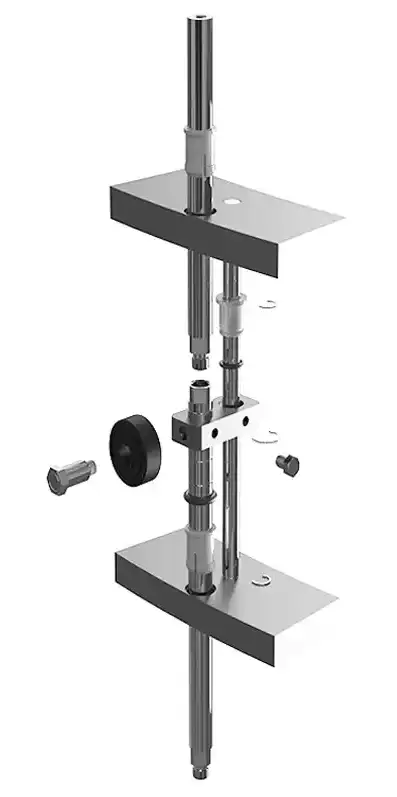

Two-Piece Slide Rod

Modular Design: The two-piece slide rod consists of two separate sections that can be detached. This modular design allows for easier replacement of individual components.

Ease of Maintenance: This design includes wrench flats on either side to separate the sections. This allows for quick and easy replacement of worn bushings without the need to remove the entire rod. This significantly speeds up maintenance tasks and reduces downtime when replacing parts.

Extended Carousel Ring Life: Regular servicing using the two-piece slide rod’s proprietary snap-in bushings helps eliminate play in the slide rods. This offers precise cycling and extension of the life of your carousel rings, while reducing downtime.

Versatile and Adaptable: Perfect for applications that demand frequent maintenance or adjustments. The modularity of the two-piece slide rod makes it adaptable to various operational needs, ensuring minimal downtime and maximum efficiency.

Choosing between a one-piece and a two-piece slide rod depends on your specific operational requirements and maintenance preferences. The one-piece slide rod offers a durable, straightforward solution for standard applications, while the two-piece slide rod provides enhanced maintenance efficiency and adaptability for more demanding environments. Whichever your operation needs, with our advanced engineering, high-quality materials, and innovative design, these slide rods enhance the performance of your bottling equipment for a better overall operation.

Interested in Ordering?