FBN produces pressure gravity filling valves that provide some of the best operation in the bottle filling industry. Engineered for peak performance, our gravity filling technology lasts longer and helps you work more efficiently. We use only the best products to manufacture every gravity filling valve. This ensures higher durability and dependability throughout the lifespan of each valve. Through our expert engineering and support, we heighten your bottle filling capabilities.

Filling Applications

Our pressure gravity filling valves are the best choice for filling both glass or plastic containers with both still or non-dense liquids. Whatever size bottle you need to fill, our filling valves fit into your operation with ease. Examples of what our pressure filling valves handle include:

- Vinegar

- Milk

- Wine

- Juice

- Acids

- Bleach

- Paint

- Spirits

- Water

- And much more!

Developed, Improved, and Implemented for more than 35 Years!

Benefits of Our Pressure Gravity Filling Valves

1

Precision Engineering and Customization

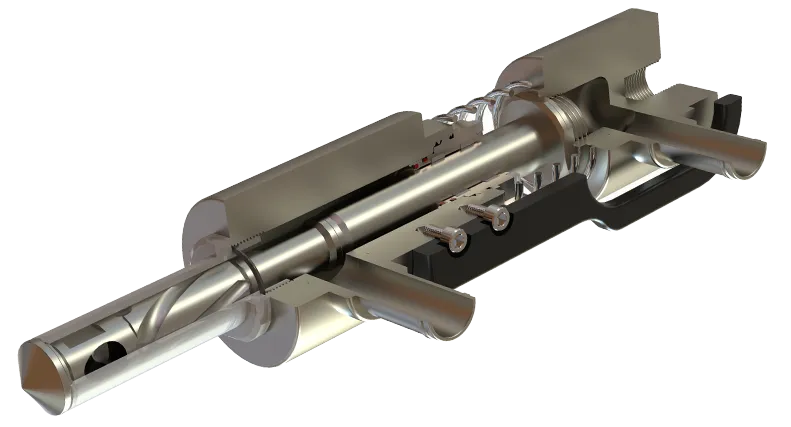

The PGF Filling Valve is a testament to precision engineering, with each component meticulously crafted from solid bar stock, using advanced CNC machining techniques. This ensures exceptional accuracy and durability. The ability to custom design the valve to fit any package makes it a versatile solution for various bottling operations.

2

Advanced Sealing System

The 4th generation sealing system is a key feature of the PGF Filling Valve, offering superior resistance to high-pressure conditions and excellent chemical resistance. This advanced sealing system ensures that the valve maintains its performance and integrity, even in demanding environments, while also being easy to clean.

3

Superior Spring Design for Longevity

The valve features a high-strength, low-fatigue spring that is custom-engineered for maximum life cycles. This design reduces the risk of material fatigue, ensuring reliable operation over extended periods and minimizing maintenance requirements.

4

Optional Alignment Fork for Enhanced Efficiency

The optional alignment fork maintains hose orientation, ensuring optimal flow and extending the life of the hoses. This feature minimizes performance issues caused by side-load stress, enhancing the overall efficiency and reliability of the bottling process.

5

Highly Polished Inner Tube for Improved Hygiene

The highly polished inner tube prevents leakage and sticking, extending the life of seals and allowing for more effective cleaning. This polished finish ensures that the valve remains hygienic and maintains optimal performance.

6

Optimized Flow-To-Vent Ratio

The flow-to-vent ratio is accurately calculated to maximize flow while minimizing bottle distortion. This balance ensures faster, more accurate bottling, while preserving the integrity of the product and the packaging.

7

Durable Engineered Polymer Outer Tube

The outer tube, made from engineered polymer, minimizes wear and enhances sealing performance. This material offers excellent chemical resistance, ensuring the durability and reliability of the valve over time.

8

Innovative O-Ringless Seal Design

The o-ringless seal design eliminates the risk of lost o-rings, reducing maintenance time and improving the overall reliability of the valve. This innovative design choice ensures consistent performance and ease of maintenance.

Tried and Tested Bottle Filling

Beyond their professional design, these valves have a long history of testing and actual use. Each piece of equipment FBN manufactures goes through a rigorous process before use. This helps us guarantee a quality product for every customer. If your operation utilizes gravity filling valves, consider FBN to help improve performance.