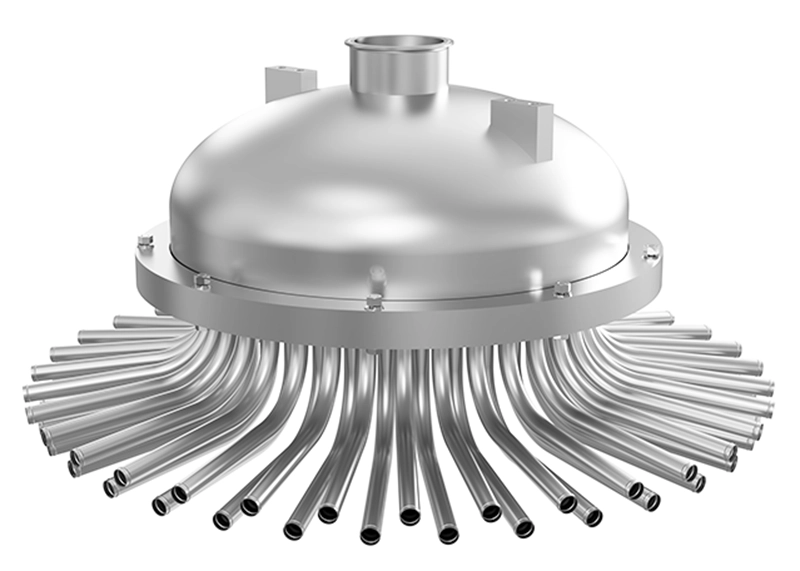

Manifolds facilitate the distribution of liquid to multiple bottles simultaneously. FBN’s standard manifolds offer reliable, fixed configurations suitable for a variety of applications, while our adjustable manifolds provide flexibility and customization to meet specific production needs. Whether you’re looking to optimize your bottling line or enhance your operational efficiency, understanding the differences and applications of these manifolds is essential for making informed decisions in your bottling operations. Explore our offerings to find the perfect solution for your needs.

Benefits of Our Bottle Filling Manifolds

Material Quality

Made from high-grade 316SSL stainless steel. This means more durability, corrosion resistance, and longevity.

Sanitary Design

Meet stringent sanitary standards. This makes them suitable for food and beverage applications. They feature polished surfaces for easy cleaning and maintaining hygiene.

Flow Control

Engineered to provide precise flow control. Through this, they minimize foaming and ensure accurate fill levels. They utilize advanced design techniques to optimize fluid dynamics and improve overall filling efficiency.

Customization Options

Can be customized with various tube diameters and fittings. This allows them to suit specific applications and product requirements. It also aids in compatibility with different packaging sizes and flow rate needs.

Differences of Standard and Adjustable Manifolds

Standard Manifold

- Our standard design features a 2:1 elliptical design for maximum flow control and eliminating foaming. It includes a one-piece handle, a polished stainless shut-off plate, a high temp UHMW shut-off shoe, and adjustable center support.

- While it offers precise flow control, the standard manifold does not have the capability to adjust for different package sizes without manual intervention and potential part changes.

- Designed for consistent performance with a specific range of package sizes and applications. It excels in providing reliable flow control and maintaining sanitary conditions.

- Typically involves a lower initial investment compared to the Adjustable Manifold, making it suitable for operations with consistent packaging needs.

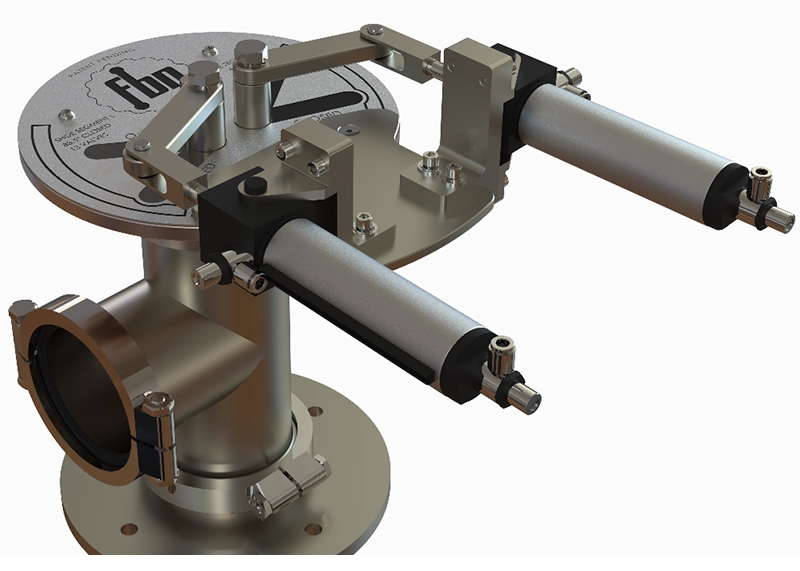

Adjustable Manifold

- Allows for on-the-fly adjustments to accommodate a larger range of package sizes with the flip of a switch or touch of a button. It is recipe-driven and pneumatically actuated, enabling precise control over the number of active filling heads.

- Provides significant flexibility by allowing operators to adjust the manifold settings quickly and easily to handle various package sizes. This feature eliminates the need for costly changeover parts and reduces downtime.

- Enhances efficiency by optimizing filling processes for different package sizes without the need for manual adjustments. It increases operational flexibility and can serve a broader customer base with varying packaging requirements.

- Requires a higher initial investment due to its advanced features and automation capabilities. However, it offers long-term cost savings by reducing the need for manual changeover of parts, minimizing downtime.

FBN’s Standard Manifold and Adjustable Manifold each offer unique benefits tailored to different operational needs. The Standard Manifold is ideal for consistent, high-precision filling with specific package sizes, while the Adjustable Manifold provides unmatched flexibility and efficiency for operations that handle a variety of packaging requirements. By understanding the similarities and differences between these two manifolds, you can choose the one that best suits your production needs and ensures optimal performance. If you need recommendations on which works best for you, our team can help!

Interested in Ordering?